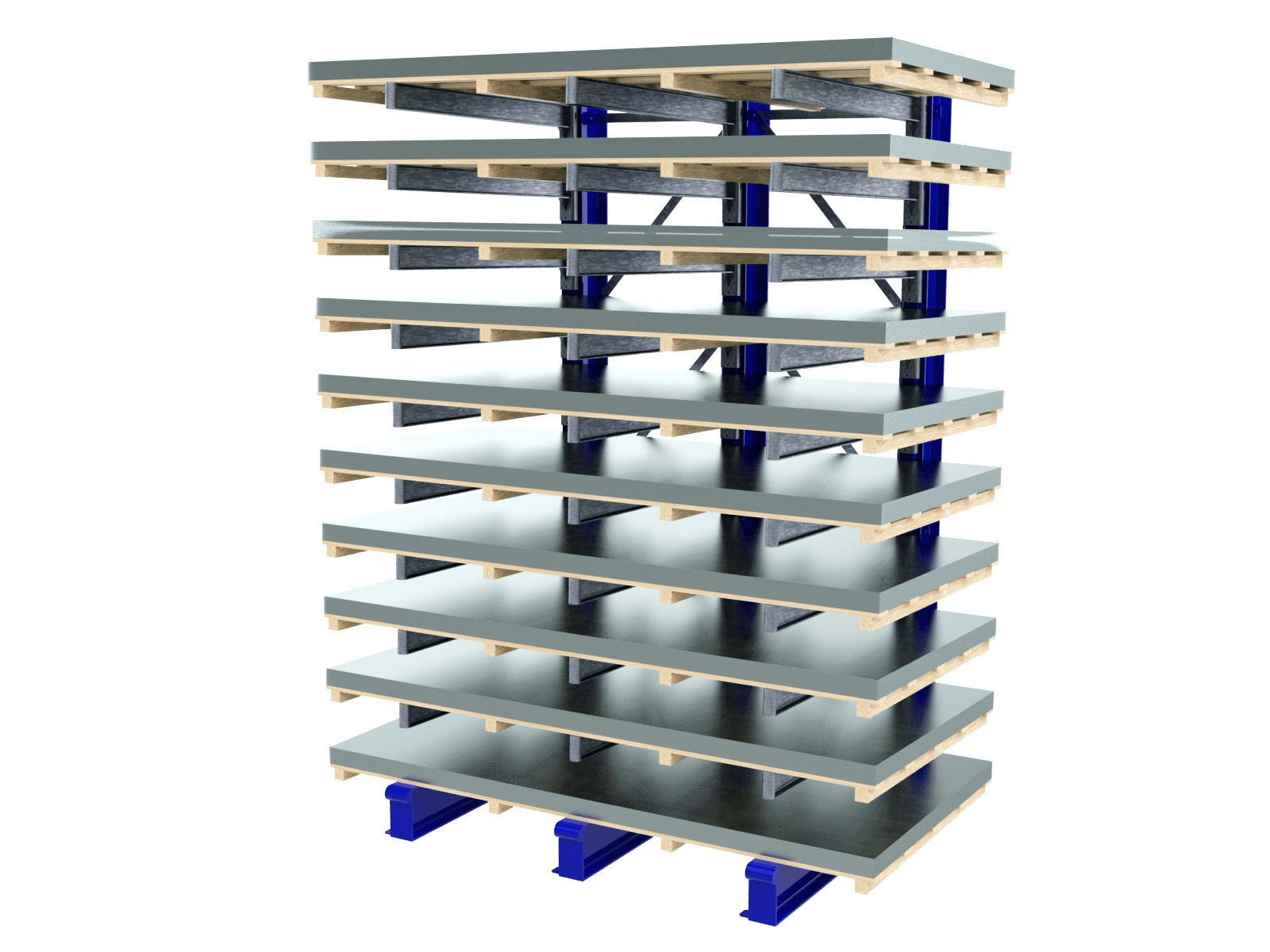

Coil storage rack for the storage of large sheet metal coils

Coil storage racks are special racks for the storage of sheet metal coils. Coil is English and means coil. In German industry, we understand coils to mean mainly sheet metal coils made of metals such as steel or aluminium. Metal wire coils are also called coils. In their coiled form, the metals require less space in storage and transport. The sheets usually represent raw materials that are sent for further processing.

What are the advantages of coil storage shelving?

First of all, the special sheet metal storage shelving systems save space in the warehouse. In a coil storage rack, you store your coils on top of each other, usually against the wall or in rows of racks. If you were to simply store the same number of coils on the floor - let's say on pallets - the storage room would quickly become overcrowded and it would be difficult to get through with corridor vehicles. Therefore, it can be worthwhile to expand an existing warehouse with a racking system for coils.

Because if you simply stacked your coils on top of each other, you would have to remove all the coils on top to reach the lowest one. In the rack, on the other hand, you can easily reach each individual coil with the forklift truck. In short: a coil storage rack simplifies storage logistics and reduces the load on the transport system.

Last but not least: The coil storage rack prevents damage such as pressure marks or deformations like flattening. Such damage to the raw material can result in expensive repairs or even render the material unusable.

What are coil storage shelves from storemaster suitable for?

Coil storage racks provide order, space and safety in the warehouse. In coil storage racks from storemaster you can safely store coils of up to 20 tonnes in each compartment and up to 150 tonnes per bay.

CoilStore® from storemaster® is a system in which you store the coils in two belts each according to the hammock principle. The belt system is patented. It flexibly adapts to the size and diameter of each coil. The advantage: The belts prevent deformation and damage. This storage system thus offers a construction for the storage facility that can be used for numerous companies and businesses that need storage technology for coils.

Furthermore offers you storemaster® the storage compartment system Splittingstore®. Here you store slit strip stacks in compartments for up to 10 tonnes load. Also SplittingStore® can be easily operated with a forklift truck. The compartments are height-adjustable, which makes storage particularly flexible.