What is a trade ad and what role does it play in logistics?

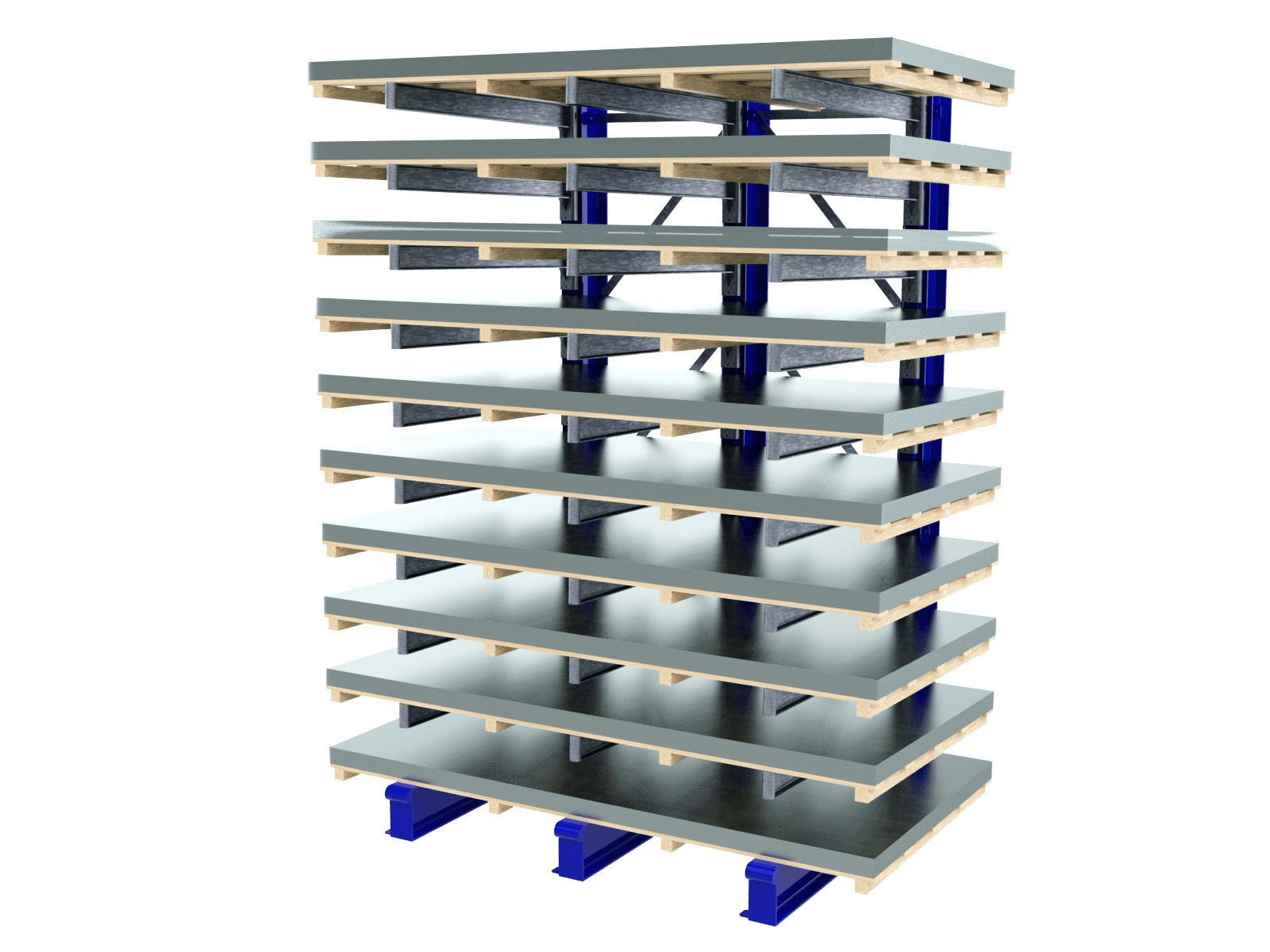

The compartment display is usually located at the storage compartments or at each staging point of a storage system, sometimes also at the upright. It can be a hand-held display with magnetic number plates, sensors or barcodes. Usually they are electronic displays such as LED light bands or displays that are connected to the warehouse IT.

The compartment display provides the order picker with information such as the item description, the item number and the quantity of the stored goods. In the electronic exchange via the warehouse management system, all participants in the logistics chain are provided with an overview of

- Stocks,

- Withdrawal quantities,

- Delivery times

- or transport routes for orders.

This makes warehouse logistics, including all picking processes, more efficient. An example of particularly good visibility is the LED strip light compartment display MULTISPOT from storemaster®. It is located on the right and left of the uprights at each storage level and makes it easier to find. Another example of compartment displays are pick-by-light systems. They consist of eye-catching lamps visible from a distance and acknowledgement buttons. Every removal ("pick") is acknowledged and every stock change is displayed in real time.

What information is typically presented in a trade advertisement for the logistics industry?

The compartment display provides the order picker or controller with information such as:

- Position and quantity of the stored goods or raw materials

- Withdrawal quantities

- Labelling and packaging of the goods

- Contact information of sender and recipient (in case of resale)

- Type of removal and means of transport, e.g. from picking trolley to lorry or ship

- Dates and routes for transport or further processing

- If applicable, also dangerous goods labels

What are the advantages of using trade ads in logistics for companies?

If the racking systems are equipped with compartment displays, all warehouse logistics processes interlock more efficiently and smoothly. For example, routes for transports from the racks and shelves or modules to assembly and further processing can be better planned and warehouse stocks optimised. Logistics becomes more competitive.

How can companies measure and optimise the effectiveness of their trade ads in logistics?

With integrated electronic applications for automatic data analysis, values such as delivery times or error rates can be measured. If the company is equipped with automation technology with intuitive operator guidance, it also improves logistics efficiency. Regular feedback from customers and suppliers also reveals sources of error and approaches for improvement. Integrated, regular monitoring of the supply chain is also necessary. This also serves the purpose of identifying delays and bottlenecks in each zone.