SplittingStore®

optimum bearing density - load distribution - diameter adjustment

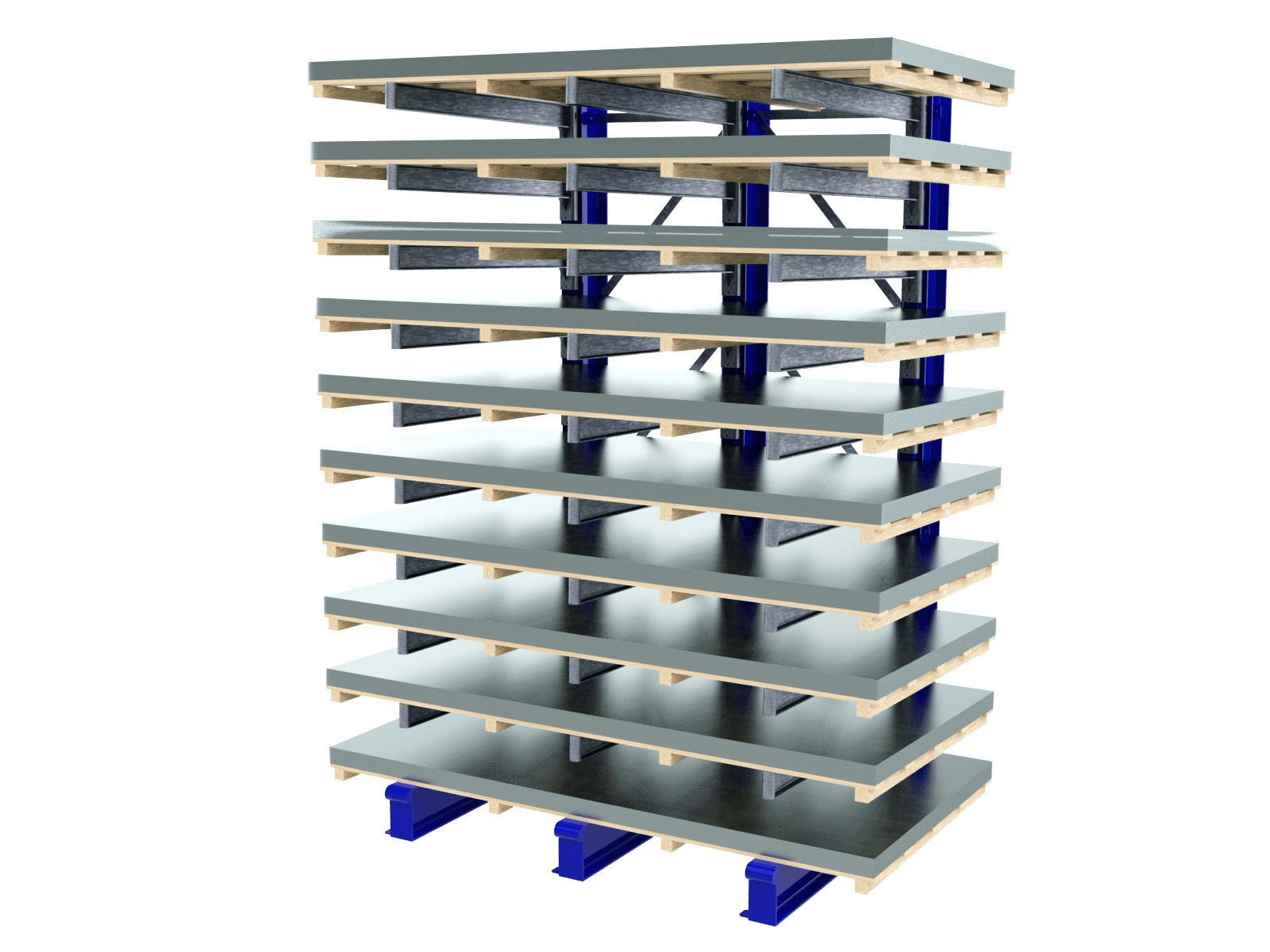

SplittingStore® vertical

Handling storage system for slit strips on storage & transport system pallets

For optimum use of the shelving (space) height, the uprights are equipped with a large number of hook-in guide rails that can be adjusted laterally in a plug-in grid to accommodate the slide-in load carriers (transport and storage flats) that reduce the shelf height requirement.

The compartment heights adapt flexibly to changing stack heights. Supported by a warehouse management programme for dynamic space management, if necessary in conjunction with a stacker scale for the purpose of creating a permanent inventory. If the coils are to remain on wooden pallets, there is the simple longitudinal traverse Maxirack.

- Operation by forklift truck

- Welded stud frame

- Flexibly adaptable to changing ring diameters

- Up to 5t shelf load

- Supported by warehouse management programme for dynamic space allocation

- Shock, abrasion and wear-resistant thanks to hot-dip galvanising in accordance with DIN EN ISO 1461

SplittingStore® horizontal

Handling storage system for slit strip stacks on storage & transport system slide-in heavy-duty flats

For optimum use of the shelving (space) height, the uprights are equipped with a large number of hook-in guide rails that can be adjusted laterally in a plug-in grid to accommodate the slide-in load carriers (transport and storage flats) that reduce the shelf height requirement.

The compartment heights adapt flexibly to changing stack heights. Supported by a warehouse management programme for dynamic space management, if necessary in conjunction with a stacker scale for the purpose of creating a permanent inventory. If the coils are to remain on wooden pallets, there is the simple longitudinal traverse Maxirack.

- Operation by forklift truck

- Welded stud frame

- Flexibly adaptable to changing ring diameters

- Up to 8t shelf load

- Supported by warehouse management programme for dynamic space allocation

- Shock, abrasion and wear-resistant thanks to hot-dip galvanising in accordance with DIN EN ISO 1461

Prepainted metal (steel, aluminium) is used in some of the most challenging applications worldwide. Handling the material requires special care and highly specialised solutions for medium and long-term storage that effectively prevent damage or negative external influences. Appropriate measures for safe coil storage are part of the sensitive tasks of intralogistics, which prevent loss of earnings or restoration costs from occurring in the first place!

Small coils can weigh up to over a tonne, while larger coils of prepainted metals can weigh between ten and twenty tonnes. Impurities and possible unevenness have a damaging effect on the material even at low pressure on the outer coil, which can continue over several coil turns and lead to considerable material losses. In this respect, a coil base should always be kept clean and smooth, but above all it should be designed in such a way that material compression or ovalisation can be avoided. In addition to a room climate and temperature management that prevents corrosion damage and helps minimise environmental influences on the material - such as rapid temperature changes that can lead to condensation - suitable highly efficient facilities are available today that make loss-free and safe storage of the coils possible.

In order to be able to meet the specific requirements of the industry in a targeted manner, corresponding slat-band racking and racking systems with particularly high load-bearing capacity have been developed, which allow optimum storage conditions for extremely heavy or bulky loads. Their shelves are either made of wood, rubber or are covered with felt and usually offer a secure hold during storage due to their V-shaped nature, so that the coils cannot start moving unintentionally due to inertial forces. As a company with decades of experience in storage technology, we offer storemaster® In addition, we offer optimal solutions that can be customised according to space requirements. Our heavy-duty handling storage system for coils up to 10 t shelf load is a highly variable storage system with shelf-height-adjustable uprights, which is equipped with patented coil pick-up load belts, guarantees even load distribution and can be adapted very flexibly to different coil diameters.

For safety reasons and to avoid material damage, it is not advisable to stack coils on top of each other. Frequent handling of material in this case would encourage damage. With one of storemaster® developed and patented heavy-duty storage system, conveniently optimised material movement becomes possible, ensuring intelligent and efficient material flow in the processing industries and specialised trade. The from storemaster® In this context, the innovative material handling storage systems produced by the company are proving to be market-leading solutions for customised slit strip storage systems worldwide - also with regard to ergonomics, economy and safety technology.

A common practice is still the delivery and storage of the coils on wooden pallets, where they can remain until use. Also for these cases storemaster® a specially developed heavy-duty shelving system with particularly easy height-adjustable support frames for slit strip ring stacks up to 5 tonnes with universal shelf dimensions for ring diameters from 800 to 1,400 mm.